MAKE A MEME

View Large Image

| View Original: | Watch jewel bearing and capstone.svg (640x420) | |||

| Download: | Original | Medium | Small | Thumb |

| Courtesy of: | commons.wikimedia.org | More Like This | ||

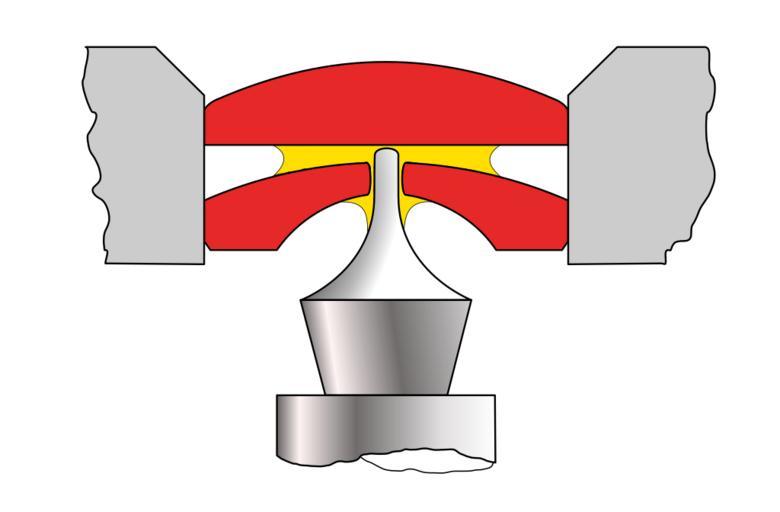

| Keywords: Watch jewel bearing and capstone.svg Drawing of a jewel bearing and capstone in a mechanical watch The bearing is sectioned through the axis The jewels red are made of synthetic ruby The lower jewel is called the 'hole jewel' the upper one is the 'capstone' or 'end jewel' This type of bearing is used in watches where friction is critical such as in the balance wheel pivots With ordinary bearings shown in Watch_jewel_bearing svg when the watch is vertical the shoulder of the shaft bears against the face of the hole jewel increasing friction This causes the watch's rate to vary with its position In contrast in this type the capstone provides a low friction surface for the rounded end of the pivot to press against instead reducing friction The hole for the pivot is slightly convex hourglass shaped so that if the pivot is not exactly vertical it won't jam in the hole The surface of the lower jewel 'bombé' is also slightly convex holding a drop of oil yellow between the jewels in contact with the pivot by capillary attraction The jewels are press-fitted into holes in the movement's supporting plates grey Information for this drawing came from Henry B Fried 1954 Bench Practices for Watch and Clockmaker Arlington Book Co Virginia USA Book 3 Ch 1 p 140-188 Own 2008-07-13 Chris Burks Chetvorno I the author release this drawing into the public domain for any use whatever Clockworks Watchworks Cross sections of bearings Balance wheels Ruby SVG machinery | ||||